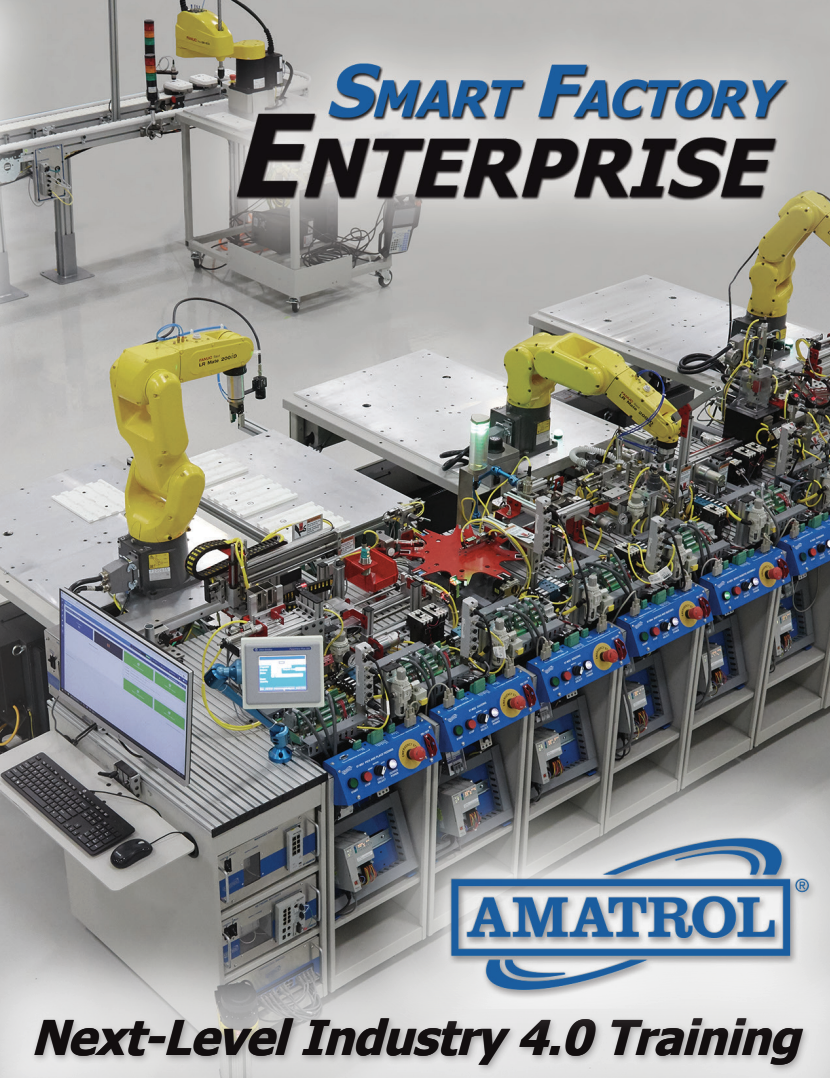

Smart Factory Enterprise System

Enterprise-Level Industry 4.0 Training for the Connected Workforce

Take Industry 4.0 training to the enterprise level. Amatrol’s Smart Factory Enterprise System integrates industrial robots, conveyors, autonomous mobile robots (AMRs), machining centers, and smart sensors into a fully connected manufacturing environment. Students gain hands-on experience with secure networks, cloud-based data analytics, MES software, and IIoT communications — the technologies powering modern smart factories.

Learners explore big data analytics, predictive maintenance, and system-wide monitoring using real industrial hardware and software. The result: workforce-ready skills in networking, automation, cybersecurity, and data-driven production management.

Key Learning Outcomes

- Secure network communications, Ethernet/IP setup, and wireless integration.

- Big Data acquisition, visualization, and cloud-based MES analytics.

- Smart maintenance and production management using real-time dashboards.

- Enterprise-level system diagnostics, OEE calculations, and production tracking.

- Mobile app monitoring for system status, alarms, and maintenance alerts.

Integrated Systems & Technologies

- Smart Sensors & Product ID: RFID, barcode, analog position, and photoelectric sensors.

- Visual Communications & SCADA: Cloud-based monitoring, mobile notifications, and collaboration tools.

- Smart Conveyor System: Material handling, machine loading, and product transfer with pallet tracking.

- Smart Robot Workstations: FANUC industrial robots with laser scanners, vision guidance, and discrete I/O controls.

- Autonomous Mobile Robot (AMR): Internal transportation between manufacturing & assembly systems.

- Machining Center: CNC mill and simulator integrated via Ethernet & network security switches.

Data Analytics & Communications

Students learn to manage real-time manufacturing and maintenance data across connected systems. Industry-relevant software provides secure access to production trends, quality data, OEE, and system health, enabling proactive, data-driven decision-making.

Integration & Flexibility

Each workstation is modular and interoperable, allowing programs to start small and scale up to a full enterprise environment. Systems can be combined or used independently for focused training in sensors, robotics, machining, or networked automation.

Expand Your Smart Factory Program

Combine the Enterprise System with Amatrol’s Smart Factory Tabletop Mechatronics (87-TMS) or Smart Factory Enterprise Upgrade options for a comprehensive Industry 4.0 pathway from classroom fundamentals to enterprise-scale automation.

-

The Smart Factory is a fully connected and flexible manufacturing system that connects its physical systems, operational information, and human assets to control manufacturing, maintenance, inventory, and supply chain operations.