Simlog's Forklift Personal Simulator puts trainees at the controls of a typical factory forklift with rear-wheel steering. Challenging training scenarios reproduce the productivity demands of modern factory, warehouse, and distribution center environments. Our intelligent Instructional Design will guide your trainees through a series of 7 skill-building Simulation Modules that emphasize safety in every exercise.

Case Study: Toyotetsu America

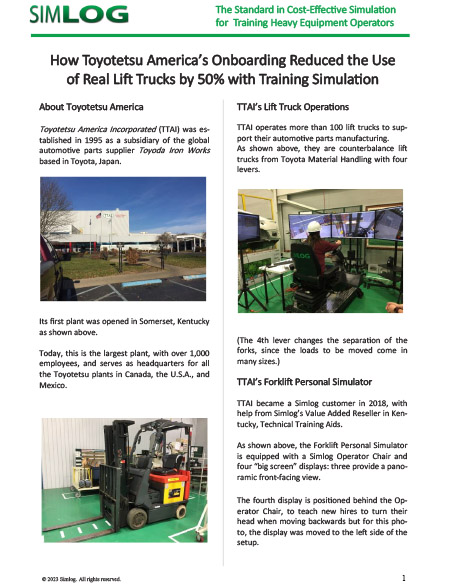

How Toyotetsu America’s Onboarding Reduced the Use of Real Lift Trucks by 50% with Training Simulation

Toyotetsu America Incorporated (TTAI) operates more than 100 lift trucks to support their automotive parts manufacturing. In 2018 TTAI became a Simlog customer and has since trained about 600 Lift Truck Operators. The onboarding program consists of three steps:

- Two days of classroom "orientation"

- Half-day of training simulation

- Half-day of “obstacle course” work at the controls of a real lift truck.

In addition, when an incident occurs on the shop floor and the “root cause analysis” points to a lift truck problem, the Floor Manager can send the operator back to the Forklift Personal Simulator for “refresher” training, to help improve the operator’s skills.

-

Item Number:FLT

-

Item Number:RLTTraining scenarios are typical of warehouses and distribution centers where racking systems are tall and spaced closely together to increase storage density. There are many software options to configure what you see and do, to reproduce the operator controls and steering behavior of the most common kinds of (real) reach lift trucks.