ABS for Method Series

The Method XL delivers precise, engineering-grade ABS prototypes with the performance features of an industrial 3D printer—now at a desktop-friendly price point. With a heated chamber, flexible heated build plate, and support for water-soluble materials, this system enables intricate, high-strength prints with ease.

Method users can now access over 600 print settings via UltiMaker Cura—the industry’s leading print preparation software. Professionally tuned profiles make it easy to slice jobs for Method X or Method XL with complete control and remote management via UltiMaker Digital Factory.

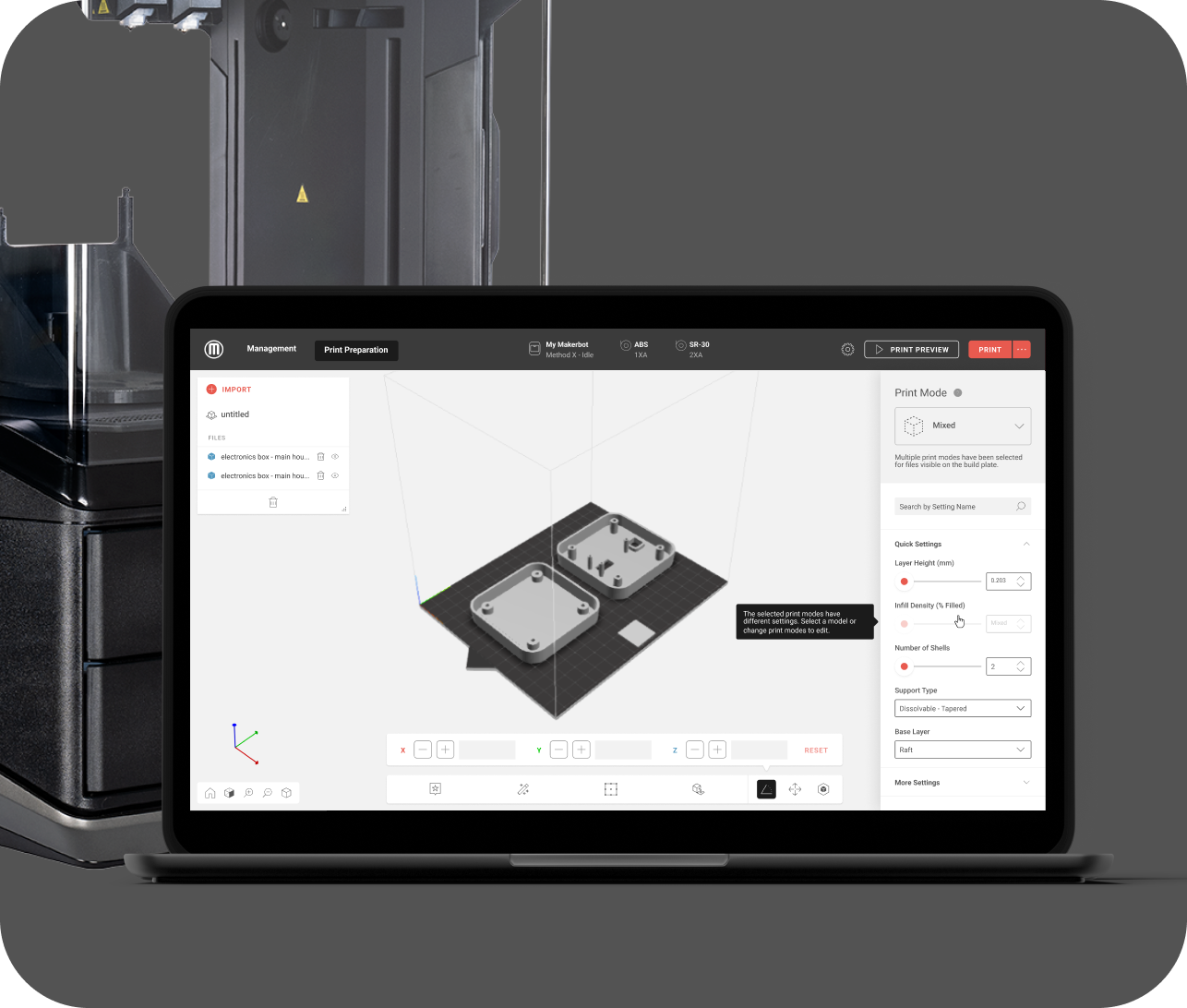

CloudPrint is a secure, cloud-based slicing and printer management platform designed specifically for the UltiMaker Method series. With an intuitive interface and streamlined workflow, CloudPrint takes you from CAD file to finished part—quickly and effortlessly. Best of all, it's completely free for all Method users.

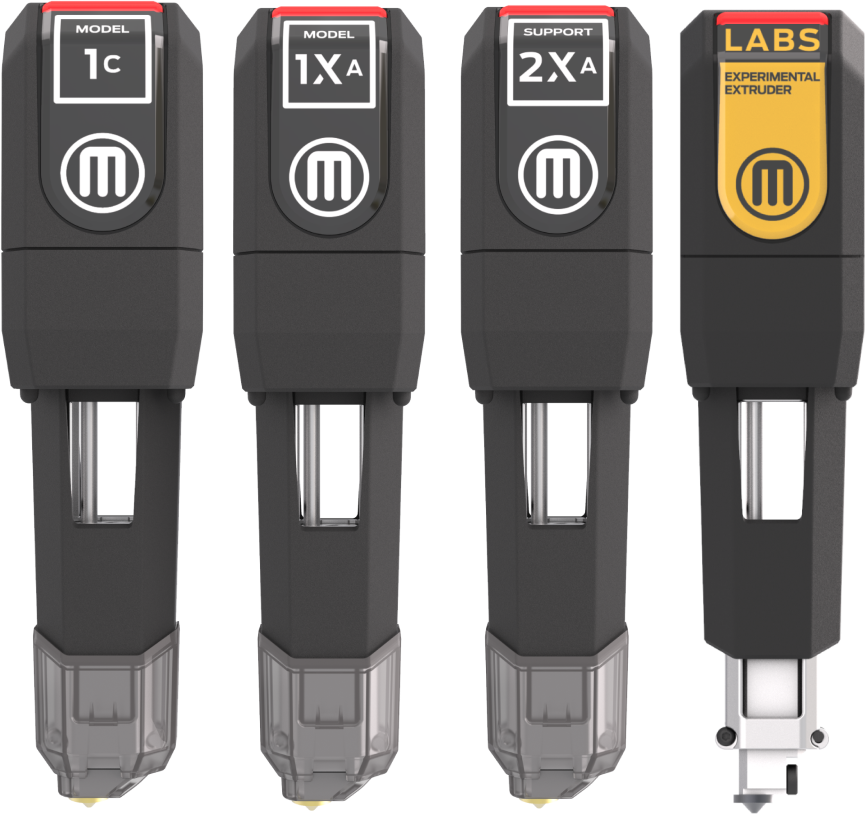

Engineered for precision, Method XL extruders feature direct-drive systems with integrated gearboxes for reliable material flow and top-tier print quality. Easily swap extruders to match your material needs—minimizing downtime and eliminating cross-contamination.

With the largest build volume of any UltiMaker 3D printer, the Method XL is the ultimate solution for engineers and designers who require space for larger components—without compromising material quality or dimensional precision.

A rigid metal frame, actively heated build environment, and optimized extruders combine to deliver reliable, injection-molding grade results.

Ready to scale your prototyping and production? Contact us today to learn more about integrating the Method XL into your engineering workflow. Let us help you print bigger, stronger, and smarter.