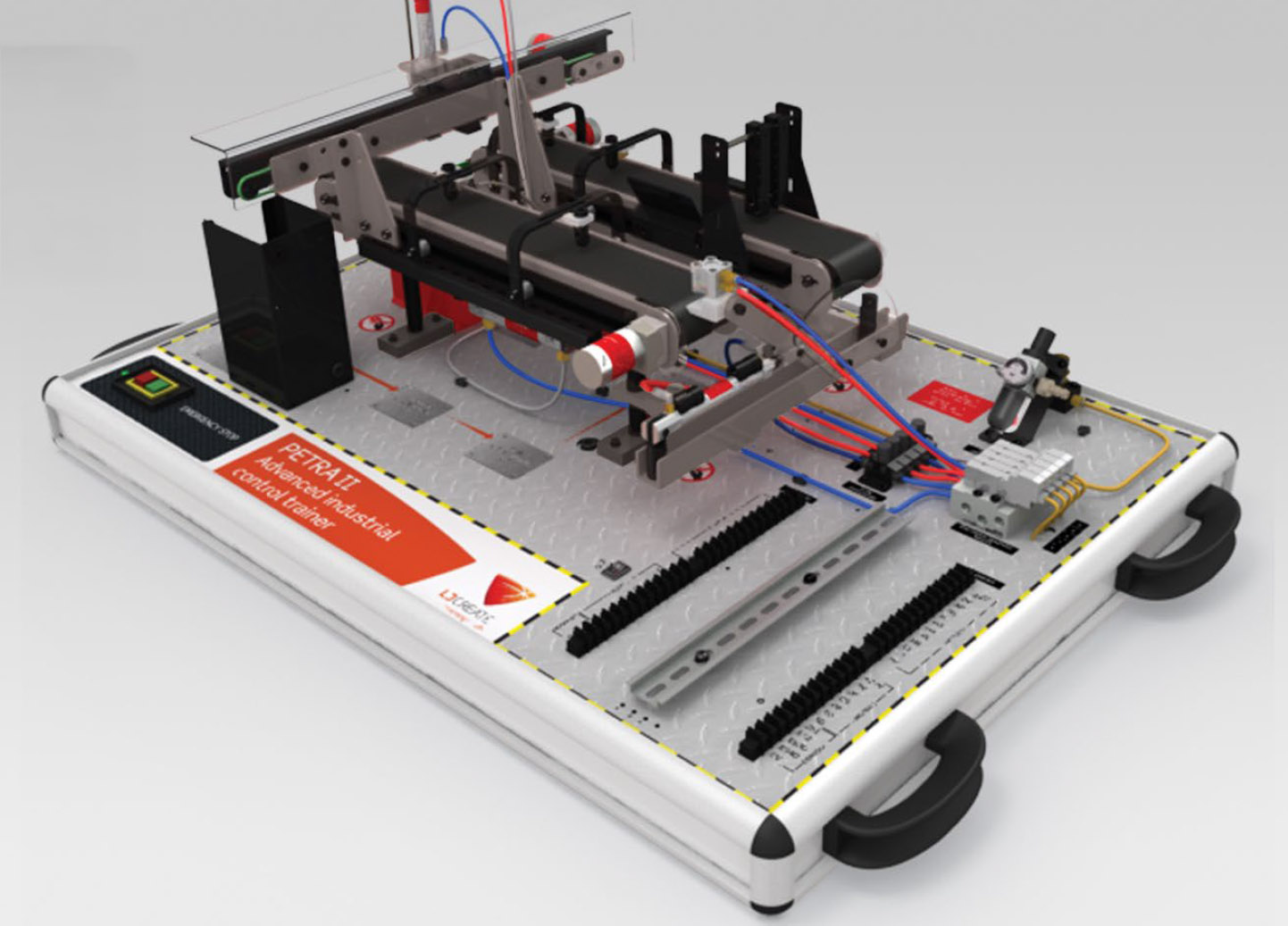

PETRA II Advanced Industrial Control Trainer

The PETRA II Advanced Industrial Control Trainer provides a complete, hands-on simulation of a factory automation process, allowing students to design, program, and troubleshoot industrial control systems using real-world components. This trainer bridges classroom theory and practical experience by combining conveyors, sensors, pneumatic systems, and PLC integration in a single, interactive learning platform.

Ideal for teaching automation, engineering maintenance, and process control, PETRA II helps students understand how industrial systems are programmed, monitored, and optimized for performance. Learners begin by writing basic control programs for individual sensors and actuators, then progress to creating full process sequences that separate “good” parts from those outside specification.

Key Features

- Dual conveyor belts and parts dispenser with assorted components—some within, and some outside specification

- Pneumatic pick-and-place plunger and two-position gripper arm for realistic motion control

- Integrated pneumatic and optoelectronic sensors for part inspection and system control

- DIN rail and screw terminal connectors for quick PLC integration and wiring

- Compatible with Allen-Bradley MicroLogix 820 and Siemens Simatic S7-1200

- Built-in switchable faults, including intermittent errors for advanced troubleshooting exercises

- Expansion ports for additional sensors and actuators to support student project work

Learning Outcomes

- Develop ladder logic programs for automated industrial processes

- Control conveyor belts, pneumatic actuators, and sensors

- Monitor and interpret data from multiple feedback systems

- Perform system fault diagnosis and maintenance

- Simulate real-world production environments safely in a classroom setting

What's Included

- PETRA II Advanced Industrial Control Trainer

- 24V DC power adapter and PLC connection leads

- Digital curriculum and user manual

Requirements

- Programmable Logic Controller (PLC)

- Computer with PLC programming software

- Compressed air supply (max 0.6 MPa / 6 bar / 90 psi)

Career Pathways

- Manufacturing ⟶ Automation & Mechatronics

- STEM ⟶ Engineering & Technology

- Industry 4.0 ⟶ Smart Factory & PLC Systems

Skills and Concepts

- PLC Programming (Ladder Logic)

- Sensor Integration & Signal Processing

- Pneumatics and Actuation Control

- Industrial Automation & Process Control

- Fault Diagnosis and System Maintenance

More Information

Specifications

- Dimensions: 41" × 26" × 20"

- Packed Weight: 83.5 lb

- Packed Volume: Approx. 25 ft³