Automated Fixture Design Arrives: fixturemate + GrabCAD Print Pro

Discover how GrabCAD Print Pro 2025 redefines 3D printing productivity.

In the world of modern manufacturing, one of the most persistent production bottlenecks isn’t equipment capacity — it’s fixture design. Whether you’re assembling aerospace components, performing quality inspections, or running hands-on manufacturing labs, the process of creating accurate, reliable fixtures has traditionally required specialized CAD expertise and long turnaround times. The fixturemate integration within GrabCAD Print Pro redefines this workflow entirely, turning what once took weeks into a process that can be completed in under 30 minutes — without sacrificing precision or quality.

For decades, manufacturing engineers have struggled with the slow, resource-intensive nature of fixture creation. A simple workholding fixture or CMM inspection jig could take days of CAD modeling, engineer review, and iterative revisions before being ready for printing or machining. Each new part design triggered another cycle of design, approval, and rework — delaying production and consuming valuable engineering time.

In an educational setting, this problem becomes even more pronounced. Students may learn the theoretical value of fixturing but rarely gain practical experience designing and deploying their own tools. Traditional CAD software often requires months of training, expensive licenses, and dedicated hardware. As a result, the fixture design process remains inaccessible to the broader student body and overly dependent on a handful of advanced users.

The outcome is a widespread bottleneck that slows innovation and limits agility. Production teams end up waiting for fixtures, projects get delayed, and both industrial and educational environments lose valuable learning or operational time. For manufacturers, the cost can reach thousands of dollars per project; for educators, it means missed opportunities to connect classroom learning with real-world problem-solving.

fixturemate, developed by trinckle and integrated directly into GrabCAD Print Pro, brings AI-powered automation to the world of fixture design. This groundbreaking tool allows users to create robust, professional-grade fixtures in as little as 20 minutes — without the need for advanced CAD skills. Users simply import a part file, define reference surfaces, and let the software automatically generate an optimized fixture model ready for additive manufacturing.

The system uses advanced geometry recognition and rule-based algorithms to analyze part shapes, identify critical surfaces, and ensure appropriate spacing, support, and rigidity. fixturemate even suggests suitable handle placements and mounting points, ensuring ergonomic and functional designs every time. The output is a fixture engineered to maintain structural integrity under real-world conditions — whether it’s for assembly, welding, or inspection.

What truly sets this integration apart is accessibility. By embedding fixturemate directly within the GrabCAD Print Pro workflow, users don’t need to export files, open additional programs, or rely on specialized designers. Everything happens in one streamlined interface. This makes it an invaluable teaching tool for technical education programs — allowing instructors to demonstrate digital-to-physical manufacturing processes within a single software ecosystem.

For educators, fixturemate provides an ideal way to teach Industry 4.0 and 5.0 principles. Students can focus on problem-solving and workflow efficiency rather than spending weeks learning complex CAD modeling techniques. For industry teams, it frees engineers from repetitive tooling tasks and empowers shop floor technicians to contribute directly to production optimization.

The range of fixtures that can be designed through fixturemate is impressive — from lightweight inspection templates to fully functional workholding systems. Each design is tailored to the geometry of your part, allowing for tight tolerances and repeatable precision. The software supports a wide variety of applications across multiple disciplines, making it equally valuable in classrooms, research labs, and production facilities.

Applications Across the Workflow

- Assembly Fixtures: Build repeatable positioning systems that maintain alignment for multi-part assemblies. Use adjustable clamping surfaces or quick-change inserts to support varied production runs. In schools, these fixtures help demonstrate assembly sequencing and lean manufacturing concepts.

- Machining and CNC Workholding: Design optimized vise jaws, custom clamps, or part supports that clear tool paths while maintaining rigidity. fixturemate allows integration with existing machine setups, reducing time spent on manual alignment and ensuring accuracy during secondary operations.

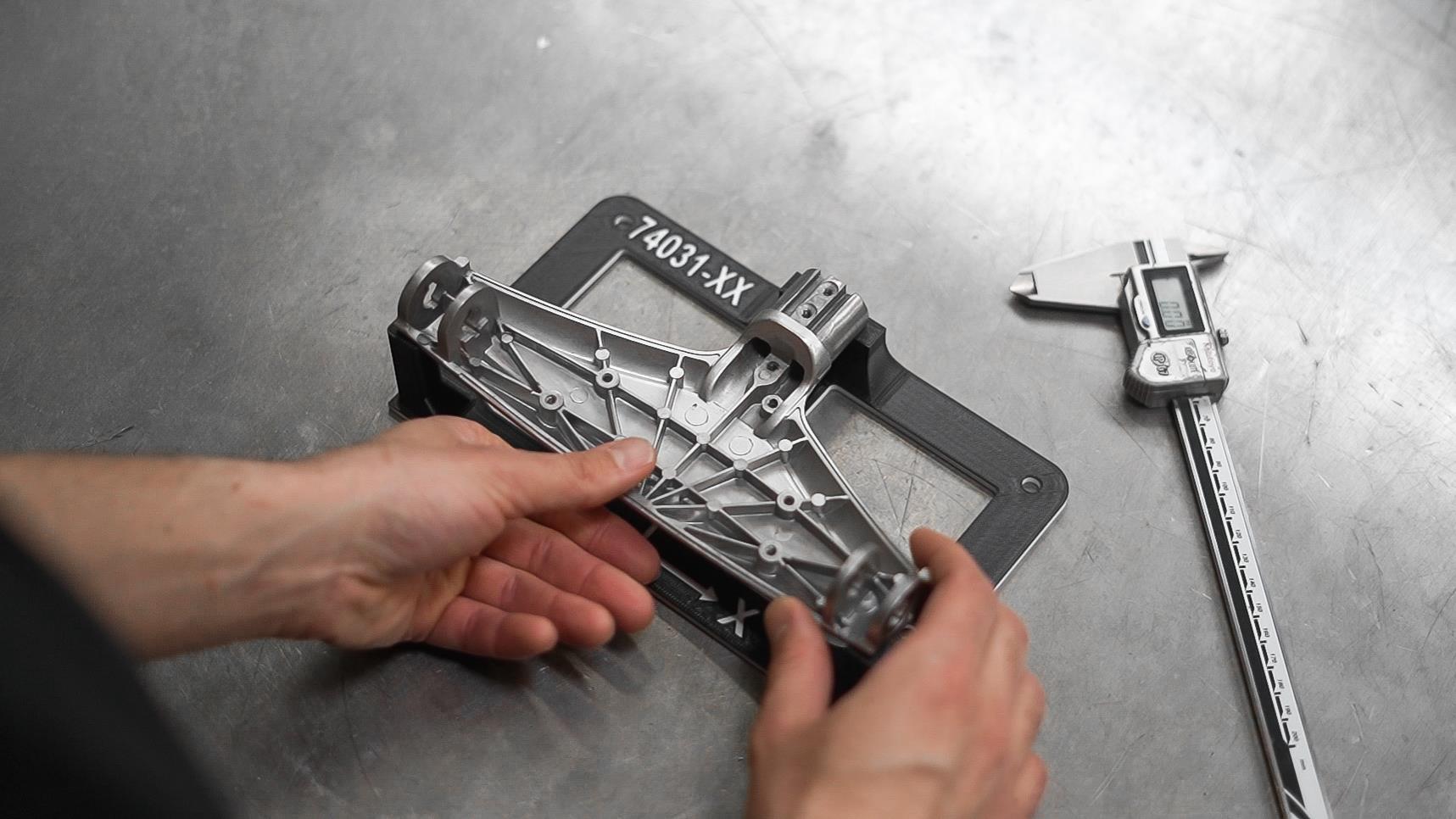

- Inspection and Metrology: Produce custom CMM fixtures, Go/No-Go gauges, or optical inspection templates that hold complex parts in repeatable orientations. Students in quality assurance programs can use these fixtures to learn inspection fundamentals and tolerance validation.

- Welding and Fabrication: Create heat-resistant jigs or tack-welding positioners to maintain consistent geometry during thermal processes. Designs can include features such as integrated guides, slots, and cooling paths to improve safety and repeatability on the shop floor.

Each of these applications showcases how additive manufacturing is reshaping traditional tooling processes. For schools, it’s a chance to give students tangible examples of digital manufacturing in action; for manufacturers, it’s a strategic way to shorten design cycles while maintaining world-class quality standards.

The measurable impact of fixturemate has already been proven in multiple sectors. Automotive suppliers have reduced fixture lead times from several days to under an hour, while small machine shops have leveraged the integration to enable same-day jig production. By replacing multi-step CAD workflows with automated generation, teams are freeing up engineering hours for innovation rather than administration.

One automotive manufacturer reported an 85% reduction in fixture setup time — from three hours to just twenty minutes. In another example, a rail industry maintenance team was able to produce overnight CMM inspection fixtures, keeping their service schedules on track. These outcomes highlight the software’s dual advantage: speed and accessibility.

In education, schools and training centers are seeing equally transformative results. Instructors now incorporate fixturemate into project-based learning modules, allowing students to design, print, and test their own tools in a single day. This immediate feedback loop reinforces engineering concepts like tolerance, fit, and functionality far more effectively than static exercises.

Beyond the time savings, fixturemate is creating a mindset shift in manufacturing and technical education. It encourages a culture of experimentation and continuous improvement. Operators who previously avoided fixture design due to complexity now participate confidently — accelerating learning, reducing rework, and boosting engagement across teams.

The cost comparison between traditional fixture design and the fixturemate workflow is staggering. Under conventional methods, each fixture can require 8–16 hours of skilled engineering labor at $75 per hour — totaling $600 to $1,200 before the first part is even produced. Add to that the two- to three-week turnaround, and the opportunity cost compounds quickly, especially when production lines sit idle.

fixturemate changes this equation entirely. Because the process takes just 20–30 minutes, a single operator can produce a usable fixture within the same shift, often for under $50 in total cost (including labor and materials). The savings are not only financial but also operational: more flexibility, faster iteration, and greater independence for both students and technicians.

ROI Snapshot: The first fixture created with fixturemate typically pays for the software investment through time savings alone. For example, replacing one outsourced fixture per week with an in-house printed version can save thousands annually. Over time, the ability to iterate designs rapidly can reduce scrap rates and improve product quality — multiplying those savings.

For schools and workforce programs, the economics are even more powerful. fixturemate eliminates the need for separate CAD licenses or outsourcing costs, allowing institutions to use existing 3D printing infrastructure to teach design-for-manufacturing skills. Students not only learn how to operate additive systems but also how to apply them strategically for lean, cost-effective production.

Bottom line: The integration of fixturemate into GrabCAD Print Pro delivers a rare combination of economic and educational value. It reduces costs, improves turnaround, and makes advanced design automation accessible to everyone — from shop floor operators to engineering students.

Experience fixturemate in Action

The combination of GrabCAD Print Pro and fixturemate represents a paradigm shift in how the manufacturing world approaches tooling and training. It replaces complexity with intelligence, long lead times with immediate results, and passive learning with hands-on, data-driven experience.

For educators, this capability gives students experience with real-world manufacturing innovation. For industry, it’s a competitive edge that reclaims time, resources, and efficiency.

Ready to eliminate your tooling bottleneck? Contact us to explore fixturemate software integration.