5 Ways GrabCAD Print Pro is Transforming Additive Manufacturing

Discover how GrabCAD Print Pro streamlines AM workflows.

Manufacturing teams and educators alike are facing mounting pressure to improve productivity, reduce costs, and modernize operations. GrabCAD Print Pro 2025 delivers the next evolution in additive manufacturing software—combining AI-driven automation, intelligent nesting, and fully integrated tooling solutions that transform your Stratasys 3D printers into connected, production-ready systems.

Here’s how GrabCAD Print Pro 2025 eliminates bottlenecks and accelerates innovation in both classroom and industry environments:

Challenge: Traditional fixture creation can take engineers days—or even weeks—tying up skilled labor and delaying production. In many facilities, the bottleneck isn’t equipment—it’s the time it takes to design and validate tooling.

Solution: The integrated fixturemate tool, developed by trinckle and embedded directly into GrabCAD Print Pro, automates fixture design in as little as 20 minutes. Using AI-driven geometry recognition, fixturemate identifies contact surfaces, adds adjustable supports, and ensures optimal rigidity—without requiring CAD experience.

- Reduce engineering dependency by enabling technicians and operators to create jigs and fixtures on the shop floor.

- Accelerate iteration cycles by printing, testing, and refining fixtures within a single workday.

- Enable schools and training centers to teach real-world design-for-manufacturing principles through hands-on experience.

Impact: Manufacturers report up to an 80% reduction in fixture design time. For educators, fixturemate provides an opportunity for students to experience Industry 5.0-level workflow automation firsthand—without needing access to advanced CAD software.

Challenge: Inconsistent print setups lead to wasted material, unpredictable quality, and inefficiencies—especially across multi-shift operations or academic labs with multiple users.

Solution: GrabCAD Print Pro introduces Manufacturing Templates, allowing teams to pre-define optimal print parameters for specific materials, part geometries, or equipment setups. Operators can apply these templates with a single click, ensuring that every print adheres to the same quality and performance standards.

- Automate key process settings such as layer thickness, infill density, and orientation for repeatable accuracy.

- Reduce the need for specialized training—students and new operators can confidently start printing within minutes.

- Guarantee consistent production quality across shifts, campuses, or multi-site facilities.

Impact: Organizations report up to a 50% reduction in setup and prep time. In training programs, templates make it possible to maintain quality control while giving students flexibility to experiment with real-world scenarios.

Challenge: Underutilized print beds and inefficient build layouts waste both time and resources. Manual part arrangement often leads to suboptimal packing density and long idle periods between jobs.

Solution: GrabCAD Print Pro’s 3D Array and AI Nesting features use intelligent algorithms to automatically position and stack parts for maximum build efficiency. These tools analyze part geometry, material, and machine parameters to find the perfect balance between throughput and quality.

- Increase production capacity by filling unused build volume automatically—up to 300% throughput gains reported in multi-part environments.

- Reduce operator input and idle time—critical for both industrial teams and educators managing shared equipment.

- Optimize overnight or unattended print runs, ensuring maximum output without constant supervision.

Impact: This feature alone can transform a single 3D printer into the output equivalent of multiple machines. Schools can simulate real-world production scheduling, while manufacturers can scale output without additional capital investment.

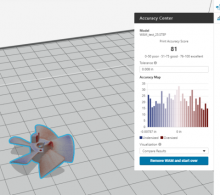

Challenge: Without accurate job costing, organizations often misprice projects—leading to profit loss in industry and budgeting confusion in education. Estimating based on material volume alone fails to capture true print time, support material, and labor costs.

Solution: GrabCAD Print Pro’s Per-Part Estimation delivers detailed cost analysis for every job, including material usage, print duration, and energy consumption. The result is a true, data-backed estimate that helps users understand the economics of additive manufacturing.

- Enable precise project quoting for service bureaus and industry clients.

- Support workforce programs in teaching cost-analysis and lean manufacturing principles.

- Compare production scenarios to select the most cost-effective build strategy.

Impact: Manufacturers can quote faster and with greater confidence, while educators gain a practical teaching tool for financial literacy in manufacturing. The feature empowers both audiences to connect technical skills with real-world business outcomes.

Challenge: Many additive programs and industrial operations use multiple printer technologies—each with its own software interface. This fragmentation leads to duplicated effort, training complexity, and wasted time switching between programs.

Solution: GrabCAD Print Pro offers a unified software ecosystem compatible with FDM, PolyJet, SAF, P3, and SLA technologies. Operators can manage all Stratasys systems through one platform—streamlining workflows from job setup to post-processing.

- Reduce training time and eliminate cross-platform confusion for educators and students.

- Enable real-time monitoring and analytics for multiple printers in one dashboard.

- Simplify maintenance scheduling and usage tracking to improve uptime.

Impact: A single, connected ecosystem gives organizations a clear overview of production performance and printer utilization. For schools, it enables cross-technology teaching without switching between programs—maximizing learning outcomes and operational efficiency.

Why It Matters for Educators and Industry Partners

Whether in a college engineering lab or an industrial facility, GrabCAD Print Pro 2025 aligns with the future of digital manufacturing education and smart factory operations. The software bridges the gap between learning and production—empowering students to master real-world workflows while helping manufacturers scale efficiently.