Electric Relay Control Learning System

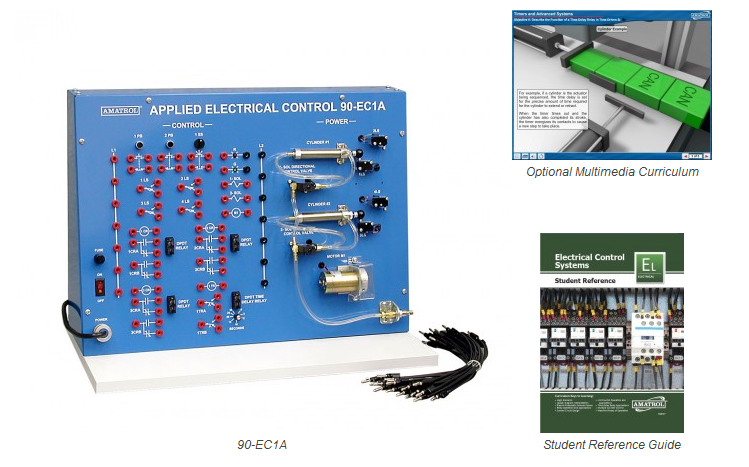

The 90-EC1-A includes a tabletop console with pre-mounted electrical control, pneumatic, and electric power components. Each component’s electrical terminals are connected to heavy-duty banana jacks, enabling learners to quickly connect and operate a variety of automation control circuits. This learning system also features a world-class curriculum covering major topic areas like control logic, ladder diagrams, sequencing control, timers, and advanced systems. The 90-EC1-A also offers optional interactive multimedia that brings these concepts alive in exciting animations, videos, and interactive exercises.

Use Real-World Components for Hands-On Skills

The 90-EC1-A features numerous real-world components including DPDT relays, double-acting cylinders, limit switches, push-buttons, accelerator switches, and solenoid operator valves. Learners use these components mounted on a tabletop, 18 gauge steel workstation to practice hands-on skills such as connecting and operating logic control circuits to energize fluid-power actuators and an electric motor. A timer relay and limit switches are used to provide sequencing control.

World-Class Speed Control Curriculum

The 90-EC1-A features a curriculum with a stunning breadth and depth of topics. Major topic areas include logic elements, ladder diagrams, electro-pneumatic solenoid valves, relay operation, and applications, limit switch operation and applications, time-delay relays and applications, multiple cylinder control, and machine modes of operation. This learning system also features optional multimedia that includes all of the topics in the printed curriculum, but in an interactive presentation with video, animations, and audio.

Optional Virtual Trainer

The Electric Relay Control Virtual Trainer replicates the hands-on components in such great detail that learners will feel like they are using the actual equipment. This virtual trainer allows learners to become familiar with common components and practice their newly acquired skills either as a stand-alone virtual solution when space is limited or while waiting for others to finish practicing on the real-world Amatrol trainer.

Expand Your Training with the 90-CT-1 Computer Control Option

The teaching capability of the 90-EC1-A can be greatly extended with the addition of the 90-CT1 Computer Control Option. The 90-CT1 uses an industrial programmable controller with a console that mounts directly to the top of the 90- EC1-A console. All inputs and outputs on the 90-EC1-A can be interfaced to the 90-CT1 to enable learners to program the PLC to control real-world automation components.

Student Reference Guide

A sample copy of this course’s Student Reference Guide is included with the learning system. Sourced from the multimedia curriculum, the Student Reference Guide takes the entire series’ technical content contained in the learning objectives and combines them into one perfect-bound book. If you would like to inquire about purchasing additional Student Reference Guides for your program, contact your local Amatrol Representative for more information.

Key Features

- Low-Cost

- Industrial Standard Components

- Table-top or Bench Mount

- Pre-Mounted Components for quick setup and inventorying

- Plug-in Quick Disconnect Component Connections

- Portable

- Quick Setup

- 24 VDC Electrical Control Power

- Multimedia Curriculum Available

- Student Reference Guide

Product Options

- Electric Relay Control - Multimedia (M16727)

- Computer Control 1 Unit (90-CT1)

- 6' Workstation (82-610)

Additional Requirements

- Compressed Air (100 psig/ 690 kPa)

- Electricity (120 VAC/60 Hz/1 phase)

Electric Relay Control - Multimedia (M16727)

The eLearning course introduces the functions of relay logic control circuits used in industrial, commercial and residential applications. Describing functions and application of functions covered in control logic include logic elements such as AND, OR, NOT, NOR, and NAND. Ladder Diagrams are explained and learners connect, operate, and design a ladder diagram using one or more logic elements. Additional concepts include Electro-pneumatic solenoid valves; sequencing control including relay operation, relay application, limit switch operation and application; and timers and advanced systems including time-delay relays, multiple cylinder control, and machine modes of operation.

Interactive Multimedia

Amatrol’s extensive, thorough multimedia covers electric relay control basics. Interactive screens paired with instructive graphics teach an array of electric relay control topics from control logic to timers and advanced systems. With the optional hardware, learners can then apply this theoretical knowledge to immediate hands-on skills. For example, learners study time-delay relays and then manually connect and operate a control circuit with a timer relay. This combination of theory and practice ingrains concepts in a learner’s mind and makes more advanced topics easier to comprehend.

Key Features

- Strong Depth and Breadth of Content

- Engaging Interactions

- Stunning 3D Animations

- Text and Audio

- Built for Self-Paced Learning

Computer Control 1 Unit (90-CT1)

Amatrol’s Computer Control 1 Learning System (90-CT1) covers how to program, operate, and interface programmable controllers in a variety of industrial applications used in the automotive, packaging, and technological assembly industries, to name a few. The programmable controller is one of the most important developments in industrial automation because of its ability to be quickly programmed to control a wide range of industrial processes and machines. Typical applications include: robots, conveyors, electric motor controls, air conditioning, process control, plastic injection molding, and CNC machines.

The 90-CT1 includes a metal, silkscreened enclosure mounted with an industrial Allen-Bradley MicroLogix 1000 programmable controller. The enclosure mounts to the Electric Relay Control Learning System (90-EC1A) to provide control of real-world electrical and pneumatic application devices. The 90-CT1’s PLC I/O terminals are wired to heavy-duty banana jacks, enabling learners to quickly connect the PLC I/O to the 90-EC1A I/O devices. This system also includes MicroLogix communication cable, student curriculum or interactive multimedia, and a student reference guide, and requires PLC programming software for SLC500/MicroLogix.

Flawless Integration of a Real-World PLC to Teach Electric Relay Applications

The 90-CT1 provides learners with actual PLC operation, programming, and event sequencing experience that can be applied to real-world processes. This learning system features a MicroLogix 1000 PLC that has ten inputs and six outputs so that learners can flawlessly integrate the PLC with the 90-EC1A. The 90-EC1A includes two pneumatic actuators controlled by solenoid-operated valves and one electric motor. The 90-EC1A also provides manual inputs with two push-button switches and one selector switch and automatic inputs with four limit switches. The combination of these learning systems allows learners to see how manual switches can be replaced by a PLC to create automated sequences by practicing skills like wiring input and output devices to a PLC and designing an actuator and motor sequence PLC program.

Strong Curriculum for PLC Skill-Building

The 90-CT1’s curriculum features a wide depth and breadth of PLC topics and skills. This curriculum covers the operation, programming, and event sequencing for this vital industrial component, as well as how it’s used to control motors and actuators. Learners study these comprehensive topics and then apply them to hands-on skills, such as designing a PLC program to jog two motors and creating a continuous cycle clamp and drill sequence PLC program. In addition to the standard print-based format, this world-class curriculum is also available in an optional interactive multimedia format that includes the same structure and level of content as the print-based version but adds extensive video, audio, 3D animations, and skill-building interactions.

Strong Curriculum for PLC Skill-Building

A sample copy of the Computer Control Student Reference Guide is also included with the system for your evaluation. Sourced from the system’s multimedia curriculum, the Student Reference Guide takes the entire series’ technical content contained in the learning objectives and combines them into one perfect-bound book. Student Reference Guides supplement this course by providing a condensed, inexpensive reference tool that learners will find invaluable once they finish their training making it the perfect course takeaway.

Key Features

- Industrial Standard Components

- Heavy Duty Welded Steel Workstation

- Plug-In Interface to External Devices

- Multimedia Curriculum Available

- Student Reference Guide

More Information

Amatrol e-Learning Course List