Basic PLC Training System – AB Micro850

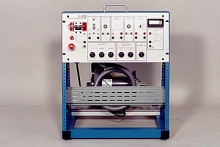

DAC Worldwide’s Basic PLC Training System – AB Micro850 (461-000) is a self-contained PLC training system that allows for self-directed instruction related to the programming and application of industrial PLCs. The basic device includes a brand name, current generation PLC, which also includes both DC inputs and outputs. The device, coupled with a comprehensive student manual, creates a complete, self-paced learning system that reflects realistic industrial and commercial applications.

This unique, multi-functional training system is based on the current generation Allen Bradley Micro850 Programmable Controller package, and includes many on-board applications with the capability of connecting to a variety of additional optional external applications. Useful within industrial training programs or in an educational setting, the Basic PLC Training System will help make this fundamental part of electrical maintenance training more memorable and effective.

Practice Hands-On Electrical Skills for Various Applications

This Basic PLC Training System utilizes industry-graded, panel-mounted components, providing durability to stand up to frequent use, and to aide learners in becoming better prepared for the tasks they will encounter on the job. It is comprised of a 16-gauge formed steel mounting frame with a welded, steel bar mounting base and includes an on-board 110/220 VAC service outlet, and an on-board 24 VDC power supply.

This system possesses a pilot light, an emergency stop switch and a system push-button circuit breaker for safety. It also includes eight (8) DC input switches, eight (8) DC output LED lights, two (2) 25-pin D-Sub input/output connectors, and provisions for accession an optional analog card. Learners will use these components to study topics, such as understanding logic gates, introducing Veitch diagrams, creating subroutines and sequencers, and much more.

The main feature of the Basic PLC Training System is the Allen Bradley Micro850 Programmable Controller assembly. In addition, this hands-on training device allows for connection to training productions related to process control, motors/motor control, sensors, PLC applications, and fluid power.

Hands-On Exercises and Learning Activities Lead to Realistic Results

DAC Worldwide’s Basic PLC Training System also features exercises and learning activities that focus more on results and less on secondary academic background information. This comprehensive training system offers true, performance-based testing provided through the use of eight (8) fault insertion switches, establishing the student’s proficiency by the number of faults uncovered within a given amount of time. The integrated course also features multiple activities, all of which include background information on the topic, hands-on experiments, and related review questions.

Course Content

Exercises include:

- Review of Electronic Concepts Related to PLCs

- Introduction to PLC Components, Terminology, and Applications

- Introduction to Numbering Systems Used in PLCs

- Understanding Logic Gates

- Introduction to Boolean Algebra

- Introduction to Veitch Diagrams

- Introduction to Ladder Logic

- Introduction to the DAC #461 PLC Trainer

- Introduction to the Allen-Bradley MicroLogix 1200 PLC

- Using RSLogix 500 to Program the MicroLogix 1200

- Working with Projects

- Using External Input and Output Elements

- Using Internal Bits

- Using Latching Logic Instructions

- Forcing External Bits on the MicroLogix 1200 PLC

- Using Timer Instructions

- Using Counter Instructions

- Using Arithmetic Instructions

- Using Jump Instructions

- Creating Subroutines

- Creating Sequencers

Application Panels for Expanded Learning Opportunity

Traffic Light PLC Application Panel (464-100)

This expansion panel includes LED traffic lights and miniature push button activation switches. This panel requires a PLC Breakout Panel (461-001), electrical (115V/60Hz/1ph electrical), and a Bench Top Panel Rack (945).

Electro-Pneumatic PLC Application Panel (464-200)

This panel includes two double-acting pneumatic cylinders, a pneumatic actuator, and limit switches. This system requires electrical (115V/60Hz/1ph) and a Bench Top Panel Rack (945).

Electro-Mechanical PLC Application Panel (464-300)

This panel includes a rotary solenoid actuator, linear acting solenoid, and limit switches. This panel requires electrical (115V/60Hz/1ph) and a Bench Top Panel Rack (945).

Analog Temperature Control PLC Application Panel (464-400)

This panel includes a heater, temperature transmitter, thermocouple probe, thermometer, and digital panel meter. This panel requires Analog Expansion Card (461-002), electrical (115V/60Hz/1ph), and a Bench Top Panel Rack (945).

BCD/Thumbwheel PLC Application Panel (464-450)

This panel includes an LED Display and a BCD Thumbwheel Display. This panel requires electrical (115V/60Hz/1ph), and a Bench Top Panel Rack (945).

Elevator PLC Application Panel (464-600)

This panel includes a simulation of 3-floor elevator. This panel requires electrical (115V/60Hz/1ph), and a Bench Top Panel Rack (945).

Pilot Devices PLC Application Panel (464-700)

This panel includes a toggle switch, a push button switch, a latching push button switch, a rotary switch, a limit switch, and eight indicator lights. This system requires electrical (115V/60Hz/1ph) and a Bench Top Panel Rack (945).

Industrial Sensors PLC Application Panel (464-800)

This panel includes a LH limit switch, a light beam, a light beam with reflective switch, a capacity proximity switch, an inductive proximity switch, and an RH limit switch. This system requires electrical (115V/60Hz/1ph) and a Bench Top Panel Rack (945).