The Evolution of FDM 3D Printing

A Journey from Invention to Innovation

In the world of additive manufacturing, few technologies have had as profound an impact as Fuse-Deposition Modeling (FDM) 3D printing. At the heart of this revolutionary technology is Scott Crump, the visionary mind behind its inception. Join us as we delve into the fascinating history of FDM, tracing its origins, development, and the transformative changes it has brought to the realm of manufacturing.

The Birth of FDM

The story begins in the late 1980s when Scott Crump, co-founder of Stratasys, stumbled upon the idea that would revolutionize the world of 3D printing. Frustrated with traditional prototyping methods, Crump envisioned a process that would allow for the layer-by-layer construction of three-dimensional objects. This vision led to the birth of FDM technology.

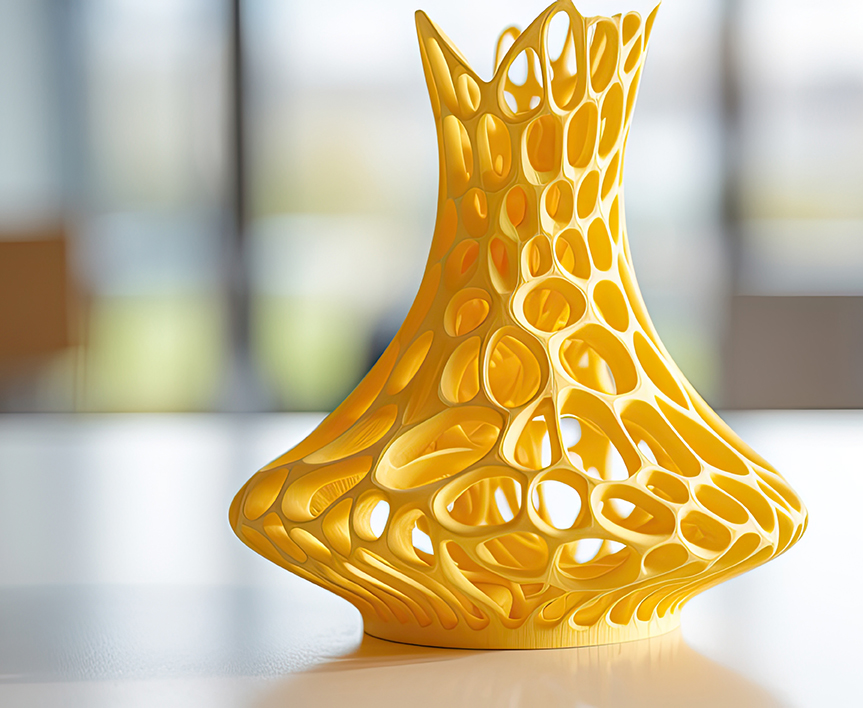

Crump's innovative approach involved extruding thermoplastic material layer by layer to create a physical model based on a digital design. This method marked a departure from traditional subtractive manufacturing techniques, opening new possibilities for rapid prototyping and the creation of complex geometries.

Early Challenges and Triumphs

In the early days of FDM, there were significant challenges to overcome. Crump and his team worked tirelessly to refine the technology, addressing layer adhesion, material compatibility, and precision issues. As they overcame these hurdles, FDM began to gain recognition for its potential in transforming prototyping processes.

The Rise of Desktop 3D Printing

As the technology matured, FDM 3D printing found its way into various industries. One of the key milestones was the development of desktop 3D printers that brought this transformative capability to smaller businesses, educational institutions, and even enthusiasts. The accessibility of FDM technology sparked a wave of creativity, enabling individuals to turn their ideas into tangible objects with unprecedented ease.

Diversification and Material Advancements

Over the years, FDM technology evolved beyond prototyping, finding applications in end-use production. Advancements in materials, including a wide range of thermoplastics, composites, and even bio-compatible substances, expanded the possibilities for FDM 3D printing. This versatility contributed to its adoption in industries ranging from aerospace and automotive to healthcare and consumer goods.

The Present and Future of FDM

Today, FDM stands as a cornerstone in the world of 3D printing. Its widespread use continues to grow, with speed, precision, and material options advancements. As the technology matures, researchers and innovators explore new frontiers, from large-scale construction projects using FDM to the development of sustainable materials for additive manufacturing.

Conclusion

The history of FDM 3D printing is a testament to the power of innovation and the transformative impact of visionary individuals like Scott Crump. From its humble beginnings as a solution to prototyping challenges, FDM has evolved into a versatile and accessible technology that reshapes how we approach design, prototyping, and production. As we look to the future, the journey of FDM continues, promising even greater possibilities and advancements on the horizon.