Advanced Manufacturing

Amatrol delivers total learning solutions for Advanced Manufacturing Training!

Tech-Labs offers technical training equipment and curriculum from Amatrol’s Advanced Manufacturing program. Amatrol’s industry-leading equipment and curriculum are developed in partnership with industry to deliver job-ready, industry-relevant skills. Working closely with companies like Caterpillar, Tropicana, and many others Amatrol has designed equipment for workplace success.

Key Features

- Highly Demanded Industry Skills: Hands-On, Job-Ready

- Individualized Self-Paced or Group Learning Flexibility

- Extensive Curriculum Spanning Basics Through Advanced

- Authentic Industrial Troubleshooting

- Durable, Industrial Equipment Designed for Effective Teaching

- Superior Multimedia Interactivity Connects With Learners

- eAssessment to Accelerate Learning, Improve Effectiveness

- Learning Anywhere, Anytime – 24 x 7

- Outstanding Support

- Computer Based Training (CBT) with Amatrol’s eAssessment (available via the web)

-

Item Number:27-MEA1Amatrol’s Mechanical Drives 1 Assessment Workstation (27-MEA1) features a compact workstation designed to effectively assess hands-on mechanical skills with both belt and chain drives.

-

Item Number:970-ME1Amatrol’s Mechanical Drives 1 Learning System (970-ME1) covers installation, operation, motor drive alignment, and various motor drive systems applications.

-

Allow your welders to double their throughput with a pre-engineered robot welding system. Both the MAC series, designed with a FANUC CRX Cobot, and the MATE series, designed with a FANUC ARC Mate robot, give endless opportunities for quick setup and ease of use.

-

The Industrial Technology Maintenance (ITM) certification features nine stackable credentials allowing students to find a job while completing each duty area.

-

Amatrol’s Packaging Program combines maintenance technician training courses with world-class simulators featuring industry-standard components so that learners are prepared for successful careers within the packaging industry.

-

Item Number:PLC HMIRockwell Automation (Allen Bradley) CompactLogix control panel electrical project kit

-

Item Number:27-PNA1Amatrol’s Pneumatics 1 Assessment Workstation (27-PNA1) features a compact workstation designed to effectively assess hands-on pneumatics skills with a variety of industry-standard components.

-

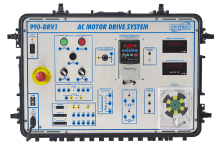

Item Number:990-DRV1FAmatrol's 990-DRV1F features industry-standard components like a Rockwell PowerFlex 4 variable frequency AC drive and a 3-phase AC motor used to teach the fundamentals of configuring and operating an AC drive. The 990-DRV1F uses FaultPro, Amatrol’s electronic fault insertion, to teach motor drive troubleshooting skills, such as drive input, motor input, and drive relay troubleshooting.

-

Item Number:990-ACDC1With the 990-ACDC1 learning system, you can teach the basics of AC and DC electrical systems in industrial, commercial, agricultural, and residential applications. The system offers industry-relevant skills including how to operate, install, design, and troubleshoot fundamental AC and DC electrical circuits for various purposes.

-

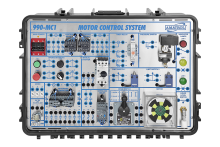

Item Number:990-MC1FSL

Amatrol’s Portable Electric Motor Control Troubleshooting Training System (990-MC1FSL) features typical industry components like a 3-phase AC squirrel cage motor. It uses 3-phase AC for power and 24 VDC for control, all packed within a space-saving, portable product. The real-world motor control components will prepare learners for work in industries where electric relay control applications are used, like conveyor control and driving large utility pumps. Teach students how to read and interpret ladder diagrams.