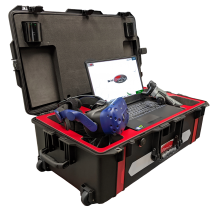

SimSpray 3.0

SimSpray is the leading training tool for the painting and coating industry. It’s an easy-to-use, turn-key training tool that provides accessible hands-on experiences with virtual reality simulations. Transform paint training with SimSpray for objective performance analysis, customizable training curriculums, and an engaging recruitment tool.

Who uses SimSpray?

Hundreds of education and workforce institutions, automotive, and manufacturing organizations use SimSpray to develop skilled workers for careers in automotive and industrial painting.

- Career and Trade Schools

- Automotive Manufacturers

- Aviation Maintenance and Repair

- Autobody Collision and Repair

- Shipbuilders and Navy Engineers

- Furniture and Cabinetry Finishers

- Paint and Coatings Manufacturers

- Workforce Development

SimSpray has been shown to save up to 50% of training costs and train proficient workers faster. Train students in a fun, engaging way, and prepare them with the core skills they'll need on the job.

SimSpray uses immersive virtual reality spray painting simulation to teach fundamental spray painting skills for HVLP processes. Visual cues, detailed scoring, pass, and performance tracking provide a continuous source of feedback. Realistic paint effects show the coat quality, thickness, and defects produced by the student’s technique. Students can master quality painting techniques through constant feedback, performance analysis, realistic painting, and experience that SimSpray offers.

SimSpray augments traditional education methods by increasing hands-on practice time, reinforcing correct techniques, growing their skills in a shorter time with less cost. SimSpray combines game design and interactive technology to create innovative training that engages students and modernizes learning.

Integrated & Customizable Curriculum

Tailor training with SimSpray's content editor, letting instructors customize training to suit their needs. Track trainee progress through learning content with SimSpray's integrated scorekeeping and performance reports.

- Projects - Use the pre-existing set or create custom projects and set performance parameters to focus on specific skills.

- Lesson Mode - Guide a student through a selected set of projects or a custom curriculum developed by an instructor.

- Objective Feedback - Coat scores include transfer efficiency, mil build, correct technique and overall performance grades.

SimSpray Benefits

SimSpray removes barriers to the learning experience. Provide hands-on training without the spray booth, materials, setup, hassle, or equipment required to start a typical coating project. Complete and repeat coating projects with ease to help trainees learn and master skills faster.

Efficient Training

Conduct efficient training sessions with accessible, repeatable projects that provide immediate results without creating waste and that require no prep or cleanup time.

Immediate Feedback

Use instant feedback, scores, and training cues to guide angle, distance, and speed, helping trainees learn and improve faster.

Customizable Learning Paths

Create a custom curriculum with projects from different industry sectors, including automotive, aerospace, construction, furniture, and cabinetry.

Effective Teaching

Set up accessible practice time and provide easy-to-understand, actionable feedback for students.

Independent Experience

Provide multiple hands-on and independent experiences tailored to meet students’ learning needs.

Collaborative Learning

Share the painter's view or observe from an inspector's view to teach through shared experiences.

Just-in-Time Training

Offer accessible, repeatable, hands-on practice sessions when and where they are needed.

More Information

Training with SimSpray is quicker, safer, and cost-efficient.