ClassMate® M

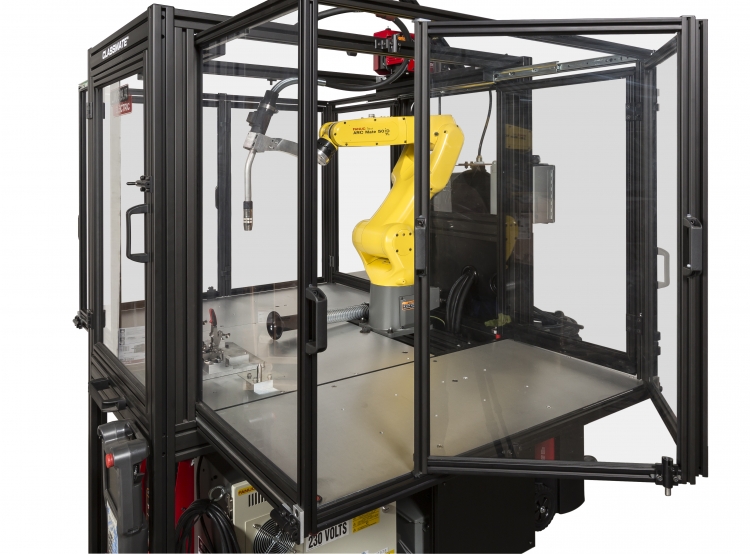

The ClassMate® M cell is a complete robotic training solution designed to meet the need for advanced manufacturing training. Instructors can teach robotic concepts in the classroom and quickly move to the lab for welding practice. Students can perform offline programming and test their skills at a manufacturing-ready robotic cell.

As businesses of all sizes compete globally, manufacturing companies are challenged to increase productivity, improve quality and reduce costs. These challenges and the critical skilled labor shortage drive manufacturers to implement automated welding fabrication. Employers everywhere are demanding that prospective employees be trained in robotic fabrication technologies. Educators are rapidly moving to respond. The ClassMate® M Robotic Trainer provides the education community with a complete advanced manufacturing solution for robotic welding training.

Features

- Compact robotic welding system

- Best economic solution

- Mobile cart, small footprint

- All-in-one system: considerable safety measures taken

- Fume extraction included

- Power source included

- Robotic Training Course and Project Based Lesson Plan Booklet included

What's Included?

- Fanuc 50iD/7L Robot - R30iB+ Mate Controller

- 120V for robot operation & fume

- Power Wave® R450 Robotic Power Source

- Auto-sourcing Input Voltage

- AutoDrive® 4R100 Wire Drive

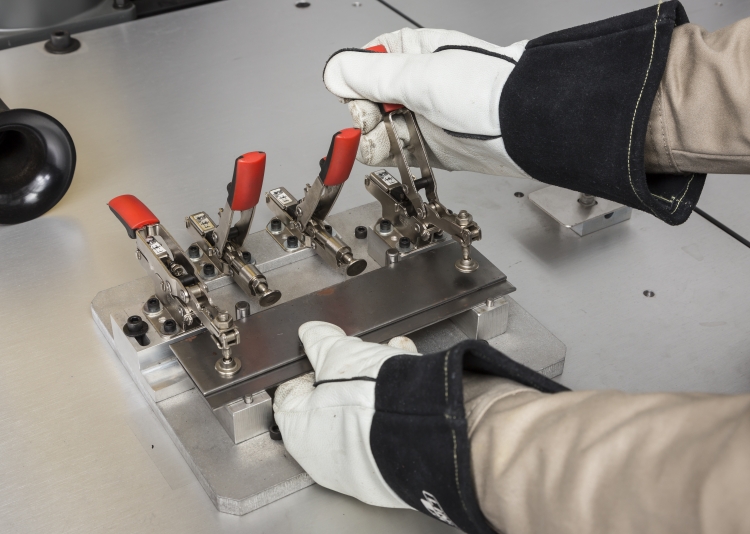

- 3-in-1 Welding Fixture

- X-Tractor® Mini Portable Welding Fume Extractor

- 2 Instructor seats in our automation courses

- Educational WeldPRO Package

- Jumpstart Package

- Gripper Package