Amatrol Basic Hydraulic Troubleshooting Learning System 950-HTB1

Amatrol’s Basic Hydraulic Troubleshooting Learning System (950-HTB1) teaches how to troubleshoot hydraulic systems and components such as hydraulic motors, directional control valves, and cylinders. The knowledge gained from the 950-HTB1’s hardware and curriculum is extremely valuable for maintenance technicians within industries like manufacturing, automotive, agriculture, construction, and many more! This learning system will also serve as a solid foundation towards attaining certifications.

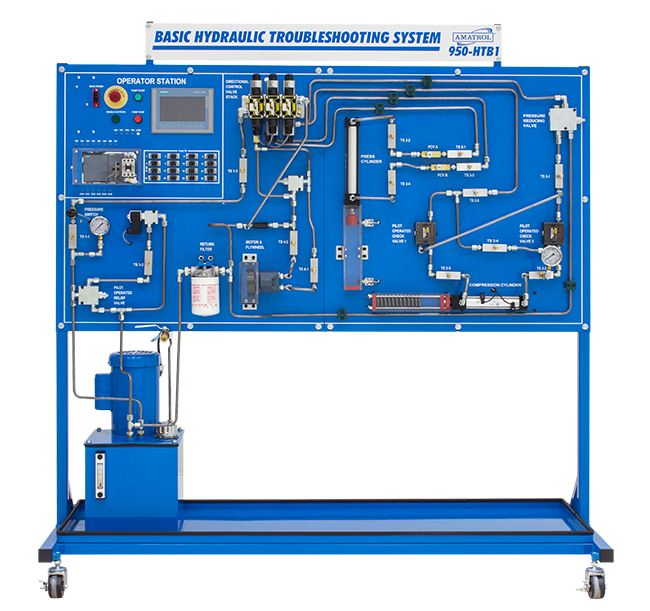

The 950-HTB1 will include a mobile workstation, control cabinet with Siemens S71200 PLC, hydraulic power distribution, four hydraulic actuator branches, a hydraulic power unit, flow meter, pressure gauge, and multimeter. Learners will use these components in real-world applications while studying major topics like hydraulic pump troubleshooting, hydraulic actuator and directional control valve troubleshooting, hydraulic valve troubleshooting, and hydraulic systems troubleshooting. This system includes industry-grade components for both greater learner comprehension and durability to stand up to frequent use.

Get Hands-On Practice Troubleshooting Over 35 Faults On Valves, Pumps, and Motors

The 950-HTB1 includes a large array of industrial-grade components on a mobile workstation, such as a Siemens S71200 PLC with HMI, a hydraulic power supply, supply and return lines, motor with flywheel, proximity switches, magnetic reed sensors, and a large selection of valves including relief, directional control, pressure reducing, check, cavitation, and air ingestion. Learners will use these components to practice hands-on troubleshooting skills that they can apply to real-world, on-the-job applications. Some of these skills include using an in-circuit test to troubleshoot a fixed-displacement pump, adjusting a cylinder cushion, troubleshooting a check valve, testing a hydraulic system by measuring fluid flow, and troubleshooting vibration in a hydraulic system.

Study the Symptoms of Hydraulic Component and System Failure for In-Depth Comprehension

The 950-HTB1’s curriculum first covers component-level faults before teaching learners how to troubleshooting system-wide problems. Sample topics include: describing the construction of three types of pressure test points, defining cavitation and explaining its effect, describing five symptoms of motor failure, describing seven symptoms of non-compensated flow control valve failure, and understand how to troubleshoot zero system pressure. This curriculum is presented in user-friendly interactive multimedia format that can be used in a classroom environment or for self-paced learning. This multimedia features stunning 3D graphics and videos, voiceovers of all of the text, and interactive activities and quizzes.

Includes Over Thirty-Five Hydraulic and Electrical Faults

The 950-HTB1 features over thirty-five manually inserted faults to help learners understand and practice common problems found in hydraulic systems. Some of these faults include: motor starter failure, defective pump, worn cylinder seals, blocked flow control valves, and blocked inlet ports.

Learning TopicsStudent Reference GuideKey FeaturesStudent Reference Guide

A sample copy of the Hydraulic Troubleshooting Student Reference Guide is also included with the system for your evaluation. Sourced from the system’s curriculum, the Student Reference Guide takes the entire series’ technical content contained in the learning objectives and combines them into one perfectly-bound book. Student Reference Guides supplement this course by providing a condensed, inexpensive reference tool that learners will fi nd invaluable once they finish their training making it the perfect course take away.

Learning Topics

- Hydraulic Pump Troubleshooting

- Flow Measurement

- Hydraulic Actuator Troubleshooting

- Cylinder Cushions and Boots

- Motor Troubleshooting

- Hydraulic Directional Control Valve Troubleshooting

- Hydraulic Valve Troubleshooting

- Hydraulic Systems Troubleshooting

- Systems Level Troubleshooting

- Machine Sequence Troubleshooting

- Machine Performance Troubleshooting

Key Features

- Features over 35 faults for learners to practice troubleshooting

- Teaches how to troubleshoot hydraulic systems and components such as hydraulic motors, directional control valves, and cylinders

- Serves as a solid foundation towards attaining certifications

- Include a mobile workstation, control cabinet with Siemens S71200 PLC, hydraulic power distribution, four hydraulic actuator branches, a hydraulic power unit, flow meter, pressure gauge, and multimeter