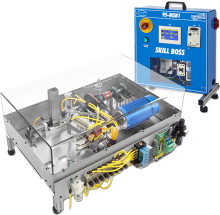

Amatrol's Skill Boss Manufacturing is a hands-on training and assessment tool for CPT+ certification that meets MSSC standards easily integrates into manufacturing programs.

Advanced Manufacturing

Amatrol delivers total learning solutions for Advanced Manufacturing Training!

Tech-Labs offers technical training equipment and curriculum from Amatrol’s Advanced Manufacturing program. Amatrol’s industry-leading equipment and curriculum are developed in partnership with industry to deliver job-ready, industry-relevant skills. Working closely with companies like Caterpillar, Tropicana, and many others Amatrol has designed equipment for workplace success.

Key Features

- Highly Demanded Industry Skills: Hands-On, Job-Ready

- Individualized Self-Paced or Group Learning Flexibility

- Extensive Curriculum Spanning Basics Through Advanced

- Authentic Industrial Troubleshooting

- Durable, Industrial Equipment Designed for Effective Teaching

- Superior Multimedia Interactivity Connects With Learners

- eAssessment to Accelerate Learning, Improve Effectiveness

- Learning Anywhere, Anytime – 24 x 7

- Outstanding Support

- Computer Based Training (CBT) with Amatrol’s eAssessment (available via the web)

-

Item Number:95-MSB1

-

Amatrol’s Smart Factory Tabletop Mechatronics system provides a full mechatronics line in a small space and is a great way to introduce Industry 4.0 to students.

-

Item Number:CRX 5iA | CRX-10iA | CRX-10iA/L | CRX 20iA/L | CRX 25iAExperience the all-new CRX Series, FANUC's latest collaborative robot designed to make installation and programming your cobots easier than ever before.

-

Item Number:APTARC50Welding programs that want to teach the latest technologies will add robotic welding to their program offering. This easy-to-program collaborative robot...

-

Item Number:890-PEC-BThe model 890-PEC-B Programmable Controller Troubleshooting Learning System teaches programming and troubleshooting of programmable controllers and their use in industrial, commercial, and residential applications. The 890-PEC-B System teaches PLC troubleshooting like no other product by providing a hands-on learning station that models real world PLC-controlled machines with up to 40 faults that can be inserted into the system.

-

Amatrol’s fluid power training systems are the best in the industry. Our learning programs are developed in partnership with industry and education to ensure that the skills are on target to support modern industry needs.

-

Amatrol’s mechanical training systems are the best in the industry. The learning programs were developed in partnership with industry and education to insure that the skills are on target to support modern industry needs.

-

Item Number:BH-85Each Basic Hydraulics training system features standard industrial grade components. This attention to quality gives students experience they would normally only get on-the-job by helping them recognize industrial components and how to troubleshoot them more effectively. Components included with Basic Hydraulics are pre-mounted on circuit panels with silk-screened labels next to each, which facilitates ease of use and identification.

-

Item Number:85-BPAmatrol’s Basic Pneumatics training system (85-BP) introduces pneumatic principles through a combination of Amatrol’s top-flight multimedia curriculum with hands-on industrial pneumatic skill-building. Topics covered in this learning system include single-acting cylinder circuits, pressure vs. cylinder force, and flow control valves, while the panels can be used to practice skills such as connecting and operating a needle valve to control actuator speed.

-

Item Number:85-EHThe Electro-Hydraulics training system includes an electrical control panel with relay control components and an electrical valve module with solenoid-operated hydraulic directional control valves and electrical/electronic sensors. These components will be used to study a variety of topics including electrical control systems, basic control devices, power devices, control relays, sequencing control, timer control, pressure control applications, and circuit applications.