Amatrol’s Basic Hydraulic Troubleshooting Learning System (950-HTB1) teaches how to troubleshoot hydraulic systems and components such as hydraulic motors, directional control valves, and cylinders. The knowledge gained from the 950-HTB1’s hardware and curriculum is extremely valuable for maintenance technicians within industries like manufacturing, automotive, agriculture, construction, and many more! This learning system will also serve as a solid foundation towards attaining certifications.

Advanced Manufacturing

Amatrol delivers total learning solutions for Advanced Manufacturing Training!

Tech-Labs offers technical training equipment and curriculum from Amatrol’s Advanced Manufacturing program. Amatrol’s industry-leading equipment and curriculum are developed in partnership with industry to deliver job-ready, industry-relevant skills. Working closely with companies like Caterpillar, Tropicana, and many others Amatrol has designed equipment for workplace success.

Key Features

- Highly Demanded Industry Skills: Hands-On, Job-Ready

- Individualized Self-Paced or Group Learning Flexibility

- Extensive Curriculum Spanning Basics Through Advanced

- Authentic Industrial Troubleshooting

- Durable, Industrial Equipment Designed for Effective Teaching

- Superior Multimedia Interactivity Connects With Learners

- eAssessment to Accelerate Learning, Improve Effectiveness

- Learning Anywhere, Anytime – 24 x 7

- Outstanding Support

- Computer Based Training (CBT) with Amatrol’s eAssessment (available via the web)

-

Item Number:950-HTB1

-

Item Number:85-MT2E Regular / 85-MT2ESL Sheathed Banana LeadsThe Motor Troubleshooting Learning System (85-MT2E) covers the testing and troubleshooting of AC and DC motors using a multimeter and a megger meter. The skills and knowledge covered by this learning system will prove invaluable for industrial maintenance technicians or anyone working in a field that uses AC and/or DC motors.

-

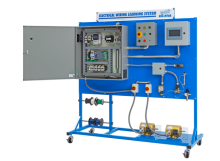

Item Number:850-MT6BAmatrol’s 850-MT6B Electrical Wiring Learning System allows students to learn electrical wiring skills hands-on.

-

Item Number:950-HM1Hydraulic systems are used in innumerable industrial areas like automotive, packaging, pharmaceutical, and food processing. This learning system provides a valuable learning experience for industrial maintenance technicians, system installers, and many others by covering hydraulic filter and fluid maintenance, fittings, seals, hydraulic hose and clamping devices, hydraulic tubing, and hydraulic component installation.

-

Amatrol Industry 4.0 Fundamentals (I4F) is a high school-based program that prepares students for high-paying Industry 4.0 careers in local industries.

-

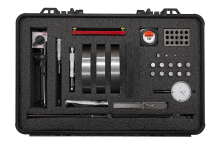

Item Number:990-MES1Learners will acquire skills such as how to measure length, accurate measurement of inside and outside dimensions, measuring both in U.S. Customary and S.I. Metric units, and collecting measurement data. The 990-MES1 contains precisely-machined and numbered parts that challenge the learner to make accurate measurements. Understanding how to perform accurate measurements is relevant to technical careers such as quality control inspector, machinist, manufacturing engineer, operations manager, and production technician. The 990-MES1’s compact size and durable case also provide for safe storage when available training space must be used to teach other topics.

-

Item Number:990-ME1Amatrol’s Portable Mechanical Drives 1 Learning System (990-ME1) covers the fundamentals of mechanical transmission systems and applications, such as how to: operate, install, analyze performance, and design basic mechanical transmission systems using chains, vbelts, spur gears, bearings, and couplings. These fundamentals can be applied to a variety of applications within the automotive, agricultural, and power industries.

-

Item Number:990-PTB1This system’s value is twofold: first it provides vital training experience for learners and professionals that will perform industrial maintenance, installation, and troubleshooting on pneumatic systems used in real-world automation machinery, packaging equipment, pharmaceutical applications, chemical handling tasks, and more. Secondly, this system features industry-standard valves, switches, and gauges all within a portable learning system that can be placed on a conference room table, shop floor desk, or practically anywhere when training space is limited.

-

Item Number:990-ELE1Amatrol’s Portable Power and Control Electronics Learning System (990-ELE1) covers how to operate, adjust, and troubleshoot electronic components, circuits, and systems used in machine applications. The portable learning system allows for on-the-go exploration of the fundamental concepts of industrial power and control electronics, such as measuring temperature, speed, and analog signals. The 990-ELE1 provides skills and topics that will be invaluable in industries like manufacturing, transportation, energy, and construction.

-

Item Number:95-MSB3The Amatrol Skill Boss Logistics offers a performance-based assessment for evaluating the skills and competencies of future supply chain automation technicians.