The Smart Factory is a fully connected and flexible manufacturing system that connects its physical systems, operational information, and human assets to control manufacturing, maintenance, inventory, and supply chain operations.

Advanced Manufacturing

-

-

Tech-Labs offers equipment and curriculum from Amatrol’s Advanced Manufacturing program. Amatrol’s industry-leading equipment and curriculum are developed in partnership with industry to deliver job-ready, industry-relevant skills. Working closely with companies like Caterpillar, Tropicana, and many others Amatrol has designed equipment for workplace success.

-

Amatrol has developed the most comprehensive, in-depth selection of online electrical training solutions available today, beginning with the basics of AC/DC electrical and moving on to more advanced topics like electrical machines, relay control, and fabrication; electrical motor control; and electrical wiring and power distribution.

-

Amatrol’s electronics learning systems combine hands-on skills and multimedia curriculum to form a training experience with unmatched breadth and depth. This product focusses on electronic drives and programmable logic controllers to give current and future workforce members the knowledge that they’ll need to excel in the their career paths.

-

To engage and reach learners with a variety of learning styles, Amatrol’s Aviation Maintenance Training program features a robust combination of learning methods to provide an outstanding learning experience that includes both comprehensive theoretical knowledge and practical, hands-on skills valuable throughout industry.

-

Item Number:85-MT2Amatrol’s Basic Electrical Machines Learning System (85-MT2) teaches electric machines commonly found in industrial, commercial, and residential applications: single phase AC motors, three-phase AC electric motors, and DC electric motors.

-

Item Number:850-HD1Amatrol’s Basic Hydraulics Training System – Double-Sided A-Frame Bench with Two Hydraulic Manifolds (850-HD1) features one set of basic hydraulics panels with the option to add another set to the opposite side to double your training capacity.

-

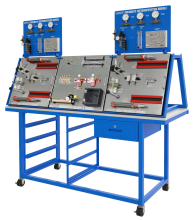

Item Number:850-PD1Amatrol’s Basic Pneumatics Learning System – Double-Sided A-Frame Bench (850-PD1) features the Basic Pneumatics Learning System (85-BP) panels mounted on a sturdy, durable A-frame bench with plenty of room for expansion.

-

Bayport Technical’s models are detailed, to-scale models that depict various industrial machines. The industrial models, which are loosely based on common equipment by popular industry leaders, include all primary features and components.

-

Bayport Technical’s trainers are hands-on training systems designed to give students real-world experience working on equipment they will encounter first-hand on the job. Each trainer has the look and feel of real industrial equipment, build with full-sized, industrial-quality components that will stand up to repeated use.