How Stratasys is helping hospitals take a patient-specific approach

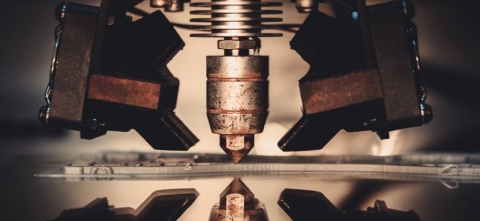

3D printing - or additive manufacturing – is expected to reach $2.3 billion by 2020, allowing for personalized care, pre-surgical planning and pre-clinical drug testing. 3D printing has its roots in the early 1980s, however recent advances in the technology allow users to 3D print objects in a wide range of materials allowing companies in many industries to prototyping, mass production, education and more.

One of the major players in the 3D printing industry is Stratasys. Covering a range of sectors from aerospace to medical, the company’s expertise in 3D printing has enabled the manufacture of various new products and solutions.

In the healthcare industry Stratasys’ main customers include medical device manufacturers, hospitals and university medical research groups and companies that are creating 3D printed devices for end-use. The company’s PolyJet technology enables its customers to 3D print medical device prototypes and patient-specific anatomical models.

Michael Gaisford, director of marketing for Healthcare Solutions at Stratasys, spoke to MPN about the work the company is doing.

“For medical device companies, our 3D printers have become the innovation engine that can enhance and accelerate the entire device life cycle. During initial development, it’s used in the rapid prototyping step– you have your concept, you want to get some feedback on it – you 3D print it and you use it to get feedback. Materials have advanced to the point where you can perform functional testing using 3D printed parts.” Gaisford explains.

Medical device partners to Stratasys are using 3D printing technology to replicate patients’ anatomy to test how well their devices work within a certain disease state. Typically, pre-clinical testing has “been done in animal models or cadavers” Gaisford says, but “the limitations of those models is that they’re not anatomically representative of a human and they often don’t have the disease state that you’re trying to treat.”

The benefits don’t stop there. 3D printed models are also giving medical device manufacturers feedback on their device’s performance faster and cheaper with more clinically relevant information compared with an animal model or a cadaver.

In hospitals surgeons can use 3D printed patient-specific models for surgical planning, giving them greater insight into their patient’s anatomy.

Learn how Stratasys, a industry leader in 3D printing, is impacting in healthcare innovation.