Benilde-St. Margaret's: Creating an Advantage for Students & Schools

Dimension 3D Printers help teach design concepts in: Architecture, Industrial Design, Medical Design, Sculpting, Mechanical Engineering, 3D Animation, Cartography, Visual Arts, Graphic Design, & Science / Math.

EQUIPPING STUDENTS WITH DESIGN ENGINEERING TOOLS TO BE COMPETITIVE

Dimension 3D Printers provide an affordable, easy to use, easy to maintain, one-step process for students and instructors to explore concepts in durable ABS plastic. It’s as simple to use as printing a file.

Dimension 3D Printers are helping high schools, technical colleges and universities extend their science, CAD and machine tool curriculums by enabling students to build functional 3D models and see their ideas first-hand.

Innovative designers, engineers, architects and manufacturers consider prototyping a critical step of the design process. As the use of CAD and 3D printing increases throught the design process, understanding this technology is critical for design students. With a Dimension 3D Printer, students and educators can now easily bring design ideas to life in ABS plastic - right from a CAD file.

Pioneering Teacher Brings the Learning Process to Life with Dimension 3D Printer Technology

As a young boy growing up in Texas, Tim Jump had no idea that his love of tinkering and fixing broken machines would someday lead him to a teaching position at a private high school in Minnesota.

“Somehow, I found a way to turn my interests growing up into a rewarding career,” said Jump. “People from the neighborhood back home are always surprised to hear that the kid who used to spend most of his time in the garage piecing together an automobile is now working to instill some of that same passion in students to get them interested in an engineering career.”

Today, Jump heads the Advanced Competitive Science (ACS) Program for students in grades 10, 11 and 12 at Benilde-St. Margaret’s School in Minneapolis. The elective program, which Jump founded nearly 11 years ago, was originally designed to teach students elements of chemistry, biology and related fields of study to prepare them to participate in science fairs. But, the curriculum gradually veered to an engineering focus and now includes three year-long courses geared to help students strengthen their problem solving skills.

“Problem solving is a non-linear process that takes time to fully grasp, which is why we spend much of our time in the early stages of the engineering program laying the foundation and showing students how to break down the elements of an engineering challenge,” said Jump.

The ACS Program has grown by leaps and bounds over the past several years. What started with a handful of interested students in the early 1990s has grown to 85 in the first-year course and several dozen in the advanced courses, thanks in large part to Jump’s orientation and recruitment efforts.

“Many schools have downsized or totally cut funding for their industrial arts programs. Our school is pretty special in that we’re able to offer students a full-fledged engineering program,” said Jump. “During their freshman year, we invite students on a special tour to get them acquainted with the possibility of getting involved with the ACS Program, showing them examples of the projects and the array of cool technology tools we use during their coursework. Our efforts have paid off, as the program has been more and more successful each year.”

One of the innovative technology tools that is always the most popular stop on the freshman recruitment tour is the school’s Dimension BST® 3D Printer, a networked, desktop modeling system that builds functional 3D models with durable ABS plastic from the bottom up, one layer at a time. “The Dimension 3D printer has allowed us to do some really exciting things with the students that wouldn’t have been possible otherwise,” said Jump. “It’s a tool that has not only helped our students succeed in the classroom, but has also given them a better understanding of design engineering concepts that have translated well as they’ve pursued their engineering careers beyond this school.”

Bringing the Learning Process to Life with Dimension 3D Printers

The first course in the three-year program teaches students how to approach problems and, as Jump puts it, learn to think and describe things like an engineer. As part of the first course, students are challenged to design and build an arm-like structure out of Lego® building blocks, then test its structural integrity by hanging it off the side of a table. The project gives students the opportunity to apply engineering principles they’ve learned throughout the year, and evaluate the structure on specific criteria, such as droop and displacement.

Once the students understand the foundational concepts of mechanical engineering, they are ready to take on the second and third courses, which focus more heavily on learning SolidWorks 3D CAD modeling software and using other advanced engineering tools, such as the Dimension 3D printer, to solve more complex engineering challenges.

Since implementing the Dimension 3D printer into his curriculum more than three years ago, Jump has been extremely pleased with how the technology has helped shift the emphasis for discovery back onto the student.

For example, during the ACS Program’s second course, students are introduced to a new structural challenge that requires them to expand on the original Lego project by creating a new building block for their structure that doesn’t exist. Before Jump implemented the Dimension 3D printer, students would design their parts and he would spend hours after school machining the prototypes, in many cases knowing all along they would not work.

Now, with the easy-to-use Dimension 3D printer, students simply send their STL design files to the machine, much like they would send a text document to a paper printer. In a short time, the students’ parts are created out of functional ABS plastic. The printer has not only saved Jump many long hours after school in the machine shop, but more importantly allowed students to fully engage in the learning process.

“I could talk to a student all day long about the importance of engineering design principles, but until they actually attempt to produce something on their own and encounter challenges and make mistakes, they won’t really be learning,” said Jump. “With the Dimension 3D printer, students are better able to experiment with their design concepts and test their engineering visions, truly understanding why a part worked or why it didn’t. The printer has really changed the whole learning dynamic for my students.”

In fact, the Dimension 3D printer has become so popular with students that many enjoy simply watching the machine create their parts. It has also become a huge selling tool to get students involved in the ACS Program.

“Students are fascinated by the printer. I could sell popcorn and soda and make a fortune,” said Jump. “They’re just mesmerized that this technology is even possible - that we can design a part, hit print and produce it in real life. It’s magic!”

RoboCup Rescue and Beyond

During the ACS Program’s third-year course, students begin to apply their engineering knowledge to more complex and advanced engineering challenges. In 2004, Jump decided to expand the challenge for these students beyond the classroom by getting them involved in the annual RoboCup Rescue engineering competition, an international event that gives students from around the world the opportunity to develop an urban search and rescue (USAR) robot capable of completing specific disaster rescue techniques.

As the only high school in the world taking part in the event, Jump knew his students would be up against extremely stiff competition.

“I was excited for the opportunity to expose the students to some real world-class engineering programs from universities worldwide,” said Jump. “I had no expectations going into the event, other than to have fun and hopefully open students’ eyes to future engineering career possibilities.”

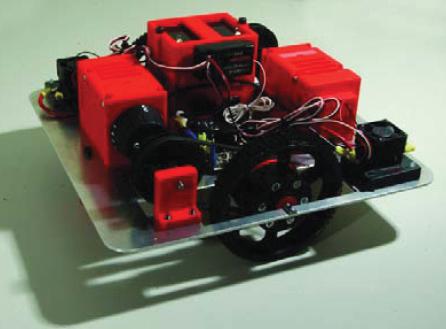

Jump’s students went to work designing their USAR robot, utilizing the Dimension 3D printer as an integral part of the development process. Because Dimension 3D printers use durable and functional ABS plastic material, students were able to design, print and use parts from the printer within the robot, saving the students time and helping to stay within Jump’s project budget.

Jump and his students brought their completed robot to the U.S. Open portion of the international competition, and were pitted against prestigious university engineering programs such as Carnegie Mellon, University of Pittsburgh and Colorado State. To the astonishment of everyone at the event, Jump and his high school team won the competition hands down, and advanced to the World Competition in Japan where they placed tenth overall. It was an amazing experience and set of accomplishments for a group of students who had only begun to understand foundational engineering principles.

“To go up against some of those university programs and come out on top was simply unbelievable,” said Jump. “Most of the robots we competed against were developed for hundreds of thousands of dollars, as compared to our robot which cost about $4,000, thanks in part to our Dimension 3D printer.”

Preparing Students for the Next Step

What Jump is particularly proud of is that the ACS Program’s success hasn’t stopped with the RoboCup competition. Because of Jump’s passion and interest in introducing students to the world of engineering, the program has enjoyed a wonderful track record of preparing students to take the next step in their engineering education.

Recently, two of Jump’s former students were admitted to Iowa State’s engineering program, and were immediately asked by professors to take part in several graduate level research projects based on their previous design engineering experience through the ACS Program. Another former student received his Masters degree at the Massachusetts Institute of Technology and went on to become a product development engineer for Medtronic, an industry-leading medical device manufacturer based in Minnesota.

“Because we’re using advanced technology tools in our curriculum, such as the Dimension 3D printer, students coming out of the program are getting significantly more respect by colleges because they can really speak engineering,” said Jump. “We have been extremely happy with what the Dimension 3D printer has brought to our program.”